OEM Part Number Cross References:

Compatibility:

| Manufacturer |

Model |

| Criticare |

1100, 2200, 5070/P, 507E/P/R, 507N/P, 507S/SD

|

| Fukuda Denshi |

Dynascope DS-7100, Dynascope DS-7200

|

| Goldway |

Vet 420A

|

| Mindray > Datascope |

Passport, Passport D, Passport EL, Passport XL

|

| Omron > Colin |

400 Series, Press Mate Advantage, Press-Mate (Old Models), Press-Mate 8800

|

| Welch Allyn |

Atlas, Atlas 6200 Series

|

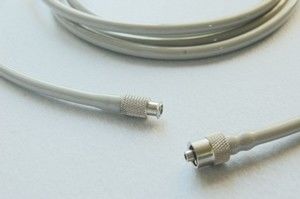

The process flow for manufacturing is as follows:

Wire cutting: The wires are cut to the required lengths.

Sheath Stripping: The outer sheath of the wires is stripped to expose the inner conductors.

Shield Twisting: If there is a shield layer, it is twisted around the inner conductors for added protection against interference.

Sleeve Crimping: The sleeves or connectors are crimped onto the ends of the wires to facilitate proper connections.

Tin Soldering: The exposed conductors are coated with tin solder to enhance conductivity and ensure secure connections.

End Pressing: The crimped sleeves or connectors are securely pressed onto the ends of the wires.

Set Plastic Shell: A plastic shell or housing is set around the assembled components for structural integrity and protection.

Electrical Test: The assembled components are tested for proper electrical functionality to ensure they meet the required specifications.

Internal Mold Forming: If needed, an internal mold is formed to provide additional support and structure to the assembled components.

Outer Mold Forming: An outer mold is formed around the internal components to provide further protection and aesthetic appeal.

Visual Inspection: The assembled product is visually inspected to check for any defects or abnormalities.

Electrical Test: Another round of electrical testing is conducted to ensure the product's electrical performance.

Thread End of Network: If applicable, the network thread end is prepared for connection.

Sheath Stripping: The outer sheath of the network thread end is stripped to expose the inner conductors.

Shield Twisting: The shield layer is twisted around the inner conductors for added protection.

Tin Soldering: The exposed conductors are coated with tin solder for secure connections.

Chips Welding: Chips or electronic components are welded onto the network thread end.

Glue Dispensing: Adhesive or glue is dispensed to secure components and provide stability.

Assembly: The various components are assembled together according to the product design.

Final Test: The fully assembled product undergoes a final round of testing to ensure it meets all specifications and standards.

Packaging: The finished product is packaged and prepared for shipping or distribution.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!